Optimization Research on Blade Pump Slider Wear Problem

This paper optimizes the blade wear problem of a vane pump. The vane pump uses the blade and the slider, the positioning ring and the inner rotor core to realize the pumping and draining function of the vane. Because the vane and the slider are in direct contact with the rotary motion, Focusing on the maximum eccentricity position and minimum eccentricity position of the blade, the IS-DYNA software is used to analyze the motion of the model. At the same time, considering the rotation of the blade, the inner rotor and the positioning ring will be impacted, and the blade will be forced to vibrate. The blade is worn out against the slider, so the inner rotor and the slider structure are optimized.

The oil pump is the heart of the engine lubrication system. The oil pump draws oil from the oil sump and continuously supplies pressure lubricant to the various friction components of the entire engine. If the oil supply of the oil pump is insufficient, the engine will lack sufficient lubrication pressure, causing severe engine wear. However, if the fuel supply is kept at a very high level, it will inevitably increase the internal loss of the engine and cause unnecessary waste.

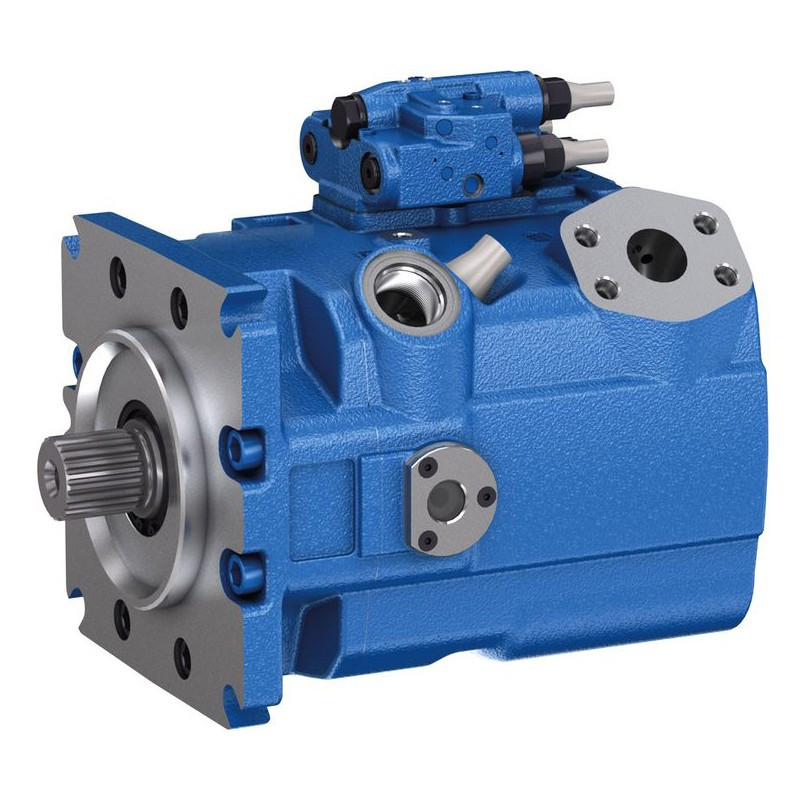

Therefore, it is necessary to provide the oil pump to supply the oil according to the demand of the engine. Therefore, with the development of technology, the oil pump provided by the actual demand of the engine for oil pressure is a variable oil pump, and the variable machine The representative product of the oil pump is the vane pump. The advantage is low cost and relatively simple structure. It can ensure the reliable operation of the engine according to the actual working requirements of the engine.

评论

发表评论