Palm kernel oil production process

Palm kernel secondary pressing process

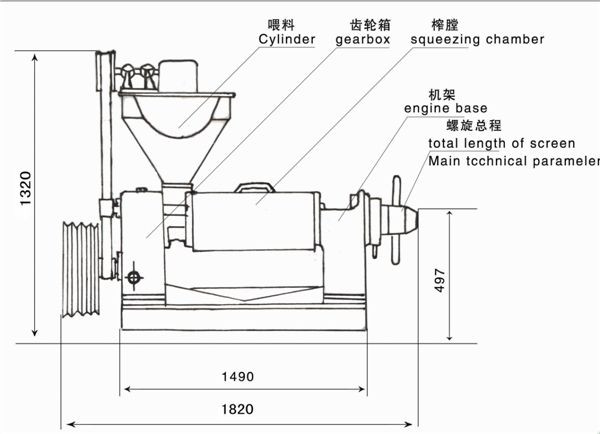

The palm kernel stored in the raw material warehouse is sent to the storage box above the primary press through the conveying device, and the material is buffered and then put into the oil press for pressing, and the pressed cake is collected and lifted and sent to the storage material above the secondary press. The box is buffered for a second press. The oil obtained from the two presses is collected in a crude oil tank and filtered and sent to the wool tank.

The processing capacity of the oil press used in the microwave drying machinery technology is generally about 15t/d, and the secondary pressing process is used. A factory with a daily processing capacity of 1000t uses about 150 oil presses (including spare presses). Excessive, resulting in a large footprint and maintenance staff and other drawbacks.

评论

发表评论